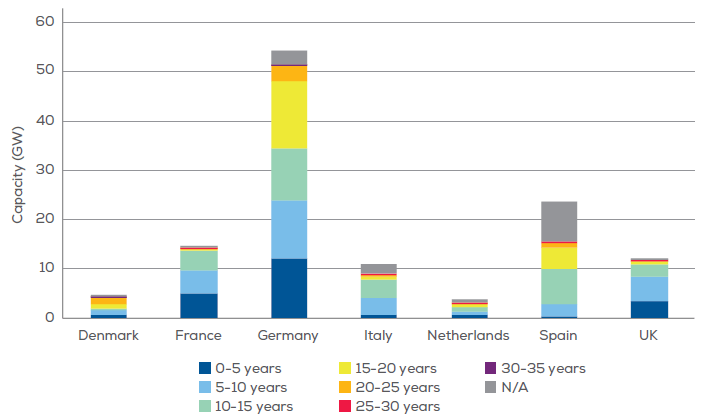

Today, the first generation of wind turbines is nearing the end of its operational life. This is a major challenge for the wind industry. On the one hand, the repowering of existing wind farms (often in the best locations) is becoming a major issue. According to Wind Europe (link), it can double the generating capacity (in MW) of a wind farm and triple the electricity output because the new turbines produce more power per unit of capacity. This is achieved by reducing the number of turbines by an average of 27%. However, operators have faced significant difficulties and delays in renewing their permits. Less than 10% of the wind turbines that will reach the end of their life in 2023 will be repowered. Many have just received a permit extension. On the other hand, the wind industry claims to be 100% circular. If composites can achieve an optimal balance of high strength-to-weight ratio, mechanical properties, design flexibility and durability, recycling these materials is a challenge whose magnitude is only beginning to be understood. According to Wind Europe, the total amount of decommissioned blade material in Europe will increase from less than 100,000 tons in 2020 to 350,000 tons in 2030. The chart below (source: Wind Europe paper) shows the age of Europe’s onshore wind fleet